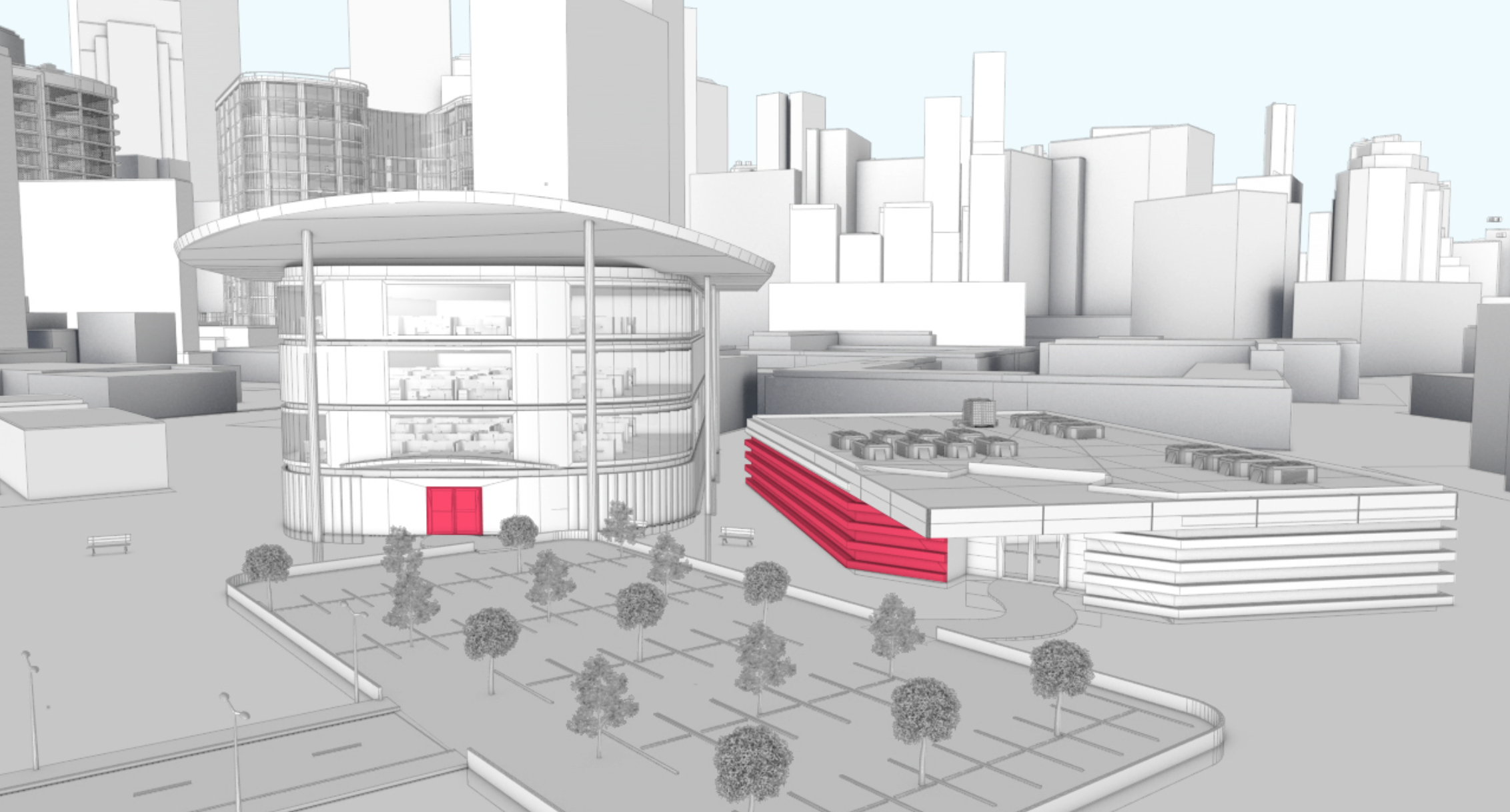

Data Center

Integrated Data Centre

Access

Authorising people access in a multi tenented building is vital for security. Ensuring that people get access to the right areas of your building is of critical importance and can’t be left to chance.

Through the access control system from Delta Controls, the entire access system is integrated with the other key building systems such as lighting and HVAC control so that management is easy and simple. Built to incorporate common reader types like Wiegand and HID formats, nearly any combination of proximity readers, card swipe, passcode or even biometric peripheral devices can be used.

Elevator access control is radically different than simply securing a door. Multi floor button press security requires powerful hardware to run quickly and smoothly every time a card is swiped. Through Delta’s commitment to co-development throughout all product lines, you can leverage the power and I/O flexibility of the eBCON system controller to match whatever specification is needed to get the job done and done right.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

On Rack – Thermostat & Temp Sensor

The temperature within the equipment racks must be preserved at all times in order to maintain the lifespan of the hardware and keep the data center functioning properly. Moderately higher temperatures force internal cooling fans to run harder and for more prolonged periods of time, drastically reducing the lifespan of the equipment. The extra runtime results in expensive replacement costs to the data center owners and greatly impacts the financial operation of the facility.

The temperature sensing requirements for data center equipment racks differ greatly from anywhere else in the controls industry. Accuracy tolerances are tighter because operational temperature targets are very precise. The differences in equipment performance and operational costs with differences of just one or two degrees are hotly debated topics in the data center industry. Reporting intervals are also required to be shorter than in regular room or duct temperature sensors. The data rack cooling equipment must be able to react to temperature fluctuations. Hotspot issues need to be escalated to facility staff within seconds of a temperature event.

Delta brings the cutting edge of communication technologies in the building automation industry to the forefront to service the data center industry. Employing wireless technology, temperature sensors can be deployed on the racks or even in the racks. They can then be moved around at will to identify problem areas, monitor ongoing maintenance, test new hardware configurations or expand ever-growing installations. Boasting PoE and Ethernet networking capabilities at the application level, any site architecture can be maintained. These network options support your temperature sensor choices, allowing you to log more data, place more sensors, or have a more flexible architecture.

On Rack – Touchscreen Display

Deliver critical information right to the field. Provide users with a system portal at the end of each rack for multi-tenanted sites, or at strategic intervals for single owner facilities. Display current temperatures and humidity readings as a heads up display. Users can also call up access data, humidity logs, and temperature trends to see how their equipment has been performing and how the environment has been maintained. Create fully customizable graphics to create a unique user experience for your occupants. The touchscreens allow personnel to make changes to the system without having to carry laptops or install separate applications.

On Rack – Access Control

Delta Controls provides a customizable access solution that allows data center facility managers to bring card access and automated security to the rack. This enables multi-tenanted facilities to allow access to individual server racks for their tenants. Setup and configuration can be done locally or offsite, giving a multitude of different options for workflow. Access logging features are built right into the system giving users the ability to see when sites were accessed. This data can be compared with work order logs, and give managers an accurate history of when their equipment was accessed. Where data security is paramount, physical security becomes a necessary precaution. For some types of data storage, such as student records or governmental data, physical security of the data is required by regulation. Delta Controls, provides facilities managers with a single platform to manage their building, lighting and their access needs. Reduce training costs, system complexity, and infrastructure cost in implementing all three systems.

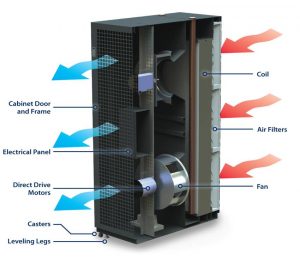

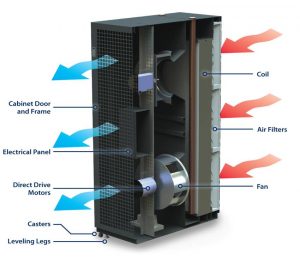

In Row Cooling

In row cooling solutions are an alternative to Computer Room Air Conditioning (CRAC) units for providing cooling in smaller data centers or in places where space is at a premium. Boasting a small footprint, and highly predictable airflow patterns, the in row cooling unit takes cooling power to the source of the heat. They are a very popular choice in constrained areas or for data centers that plan on frequent expansion. Pair up a Delta Controls wireless temperature sensing solution for a truly modular approach to data center expansion.

In row cooling units come in many forms. Refrigerant or water based, capable of operating using high return temps or dependent on lower temperatures for operating efficiencies. Designed to work with an air containment system or designed to allow free exhaust of hot air into the data center space. There are many different configuration options when it comes to in row cooling systems. Delta Controls allows you to integrate with in row cooling equipment directly over BACnet or through Modbus as well as providing a full complement of I/O options for direct control. Network options include Ethernet at the application level and Power over Ethernet, allowing some of the most advanced architectures in the industry to be employed in your data center or server area.

Dedicated Data Centre

Access

Authorising people access in a multi tenented building is vital for security. Ensuring that people get access to the right areas of your building is of critical importance and can’t be left to chance.

Through the access control system from Delta Controls, the entire access system is integrated with the other key building systems such as lighting and HVAC control so that management is easy and simple. Built to incorporate common reader types like Wiegand and HID formats, nearly any combination of proximity readers, card swipe, passcode or even biometric peripheral devices can be used.

Elevator access control is radically different than simply securing a door. Multi floor button press security requires powerful hardware to run quickly and smoothly every time a card is swiped. Through Delta’s commitment to co-development throughout all product lines, you can leverage the power and I/O flexibility of the eBCON system controller to match whatever specification is needed to get the job done and done right.

Power Distribution – Monitoring/Reporting

The power distribution room of any data center houses some of the most vital systems in the building. The classification of the entire data center hangs on the power center’s ability to maintain the facility’s functionality in the event of a power outage or internal system failure. Redundant systems are employed in the design of the power structure, as are battery backups, surge protection, and backup generators. When a loss of power occurs, it’s not the data that’s in the system that’s at the greatest risk; it’s the data that is still pouring in. If the data center experiences a partial loss of power even for seconds, massive amounts of incoming data could fail to be logged. Data that has already entered the system has been written to hard drives, with most facilities offering multiple backups of the same data.

It’s easy to see how critical it is to monitor and maintain the power distribution systems within data centers. Data center classification is denoted by a Tier system, such as Tier II, Tier III, and Tier IV. One of the primary criteria is maintenance of system “uptime”. When a data center’s primary processing and storage systems are functioning nominally, the classification of the data center is going to rest heavily on the power distribution system’s ability to maintain uptime even in the case of a loss of power to the building.

Power distribution data must be easy to access by multiple persons working within the facility and needs to be accurately logged so reports can be generated. The BAS system can take information from what are normally disparate or proprietary systems and make it available to multiple people within the facility. Staff need to be immediately alerted to fault detection or equipment in danger of becoming faulty and the BAS can act as a bridge, providing alarm notification capabilities to the power distribution system to a wider audience of staff who need to be informed of power events, or equipment failures. In addition, through energy metering and the addition of monitoring or analytics, the system’s energy data can analyzed and opportunities to increase energy efficiency can be sought out.

Power Distribution – Touchscreen Display

A touchscreen in or in front of the power distribution room allows local staff to gain instant access to BAS and energy data stored within the system. It also allows staff to make changes to the system using customized graphics and configuration screens. The touchscreen is a powerful tool onsite allowing for a more efficient workflow without requiring specialized software on a technician’s laptop. It also allows for a wider cross training of staff enabling access for more personnel that require interaction with the system’s historical data or who need the ability to set schedules, change lighting, interact with cooling systems, or perform system diagnostics.

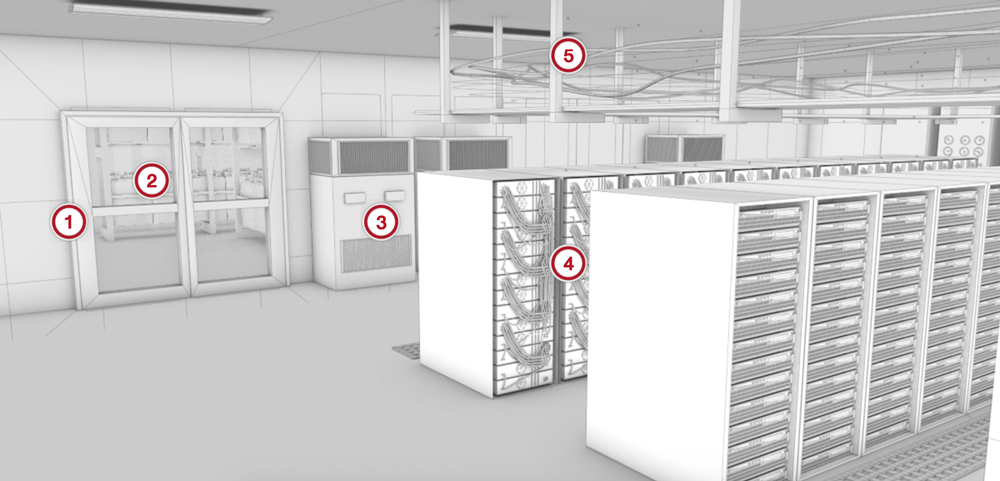

CRAC Unit – Direct Control

A Computer Room Air Conditioning (CRAC) unit is a specialized air conditioning unit for data server environments that contains equipment to cool air, monitor temperature and humidity. To make CRAC units a perfect fit for their demanding application, powerful DX or hydronic cooling, fast communication speeds, low fault tolerances, and redundant fail-safes all go into the design. As they are located in close proximity to the equipment they serve, most CRAC units are only required to transfer air a comparatively short distance away. CRAC units are often located in the same rooms as the server equipment or are located just a room away. Most commonly, underfloor ducting is used to channel the cool air from the CRAC unit to the servers where the air is channeled through various patterns of floor grates.

Many CRAC units will come from the manufacturer with some level of automation package integrated into the unit. More advanced control strategies will require the BAS system to deeply integrate with the CRAC unit to allow for a customized sequence of operation or to integrate additional HVAC equipment into the sequence to work in tandem with the CRAC unit. Auxiliary cooling equipment could be required in the surrounding areas or a supplemental dehumidification system could need to work in tandem with the CRAC unit’s operation. Direct control of the CRAC unit’s I/O may be achieved through BACnet or Modbus integration but some units allow for direct terminal wiring allowing some level of direct control using a standard I/O controller. The Delta system provides multiple I/O options as well as sensor and display options such as local touch screen interface amd wireless sensor gateways.

CRAC Unit – Packaged System Integration

A Computer Room Air Conditioning (CRAC) unit is a specialized air conditioning unit that contains equipment to cool air, monitor temperature, and humidity, for data server environments. Powerful DX or hydronic cooling, fast communication speeds, low fault tolerances, and redundant fail safes all go into the design to make CRAC units a perfect fit for their demanding application. Most CRAC units are only required to transfer air a comparatively short distance away as they are located in close proximity to the equipment they serve. Often times CRAC units are located in the same room are the server equipment or are located just a room away. Most commonly, underfloor ducting is used to channel the cool air from the CRAC unit to the servers where the air is channeled through various patterns of floor grates.

CRAC units can operate in a standalone fashion with packaged control options but this bypasses the efficiencies that can be gained by having the equipment working and communicating as part of a larger system. When tied into a larger building communication system, opportunities for gathering of system analytics, energy conservation through load shedding and best process analysis all become available. BACnet or MODbus capable CRAC units have multiple opportunities for sensor and user interface upgrade on a Delta network. Touchscreens, wireless sensors, or additional I/O can be added at the device to expand the control strategy around the CRAC unit.

On Rack – Thermostat & Temp Sensor

The temperature within the equipment racks must be preserved at all times in order to maintain the lifespan of the hardware and keep the data center functioning properly. Moderately higher temperatures force internal cooling fans to run harder and for more prolonged periods of time, drastically reducing the lifespan of the equipment. The extra runtime results in expensive replacement costs to the data center owners and greatly impacts the financial operation of the facility.

The temperature sensing requirements for data center equipment racks differ greatly from anywhere else in the controls industry. Accuracy tolerances are tighter because operational temperature targets are very precise. The differences in equipment performance and operational costs with differences of just one or two degrees are hotly debated topics in the data center industry. Reporting intervals are also required to be shorter than in regular room or duct temperature sensors. The data rack cooling equipment must be able to react to temperature fluctuations. Hotspot issues need to be escalated to facility staff within seconds of a temperature event.

Delta brings the cutting edge of communication technologies in the building automation industry to the forefront to service the data center industry. Employing wireless technology, temperature sensors can be deployed on the racks or even in the racks. They can then be moved around at will to identify problem areas, monitor ongoing maintenance, test new hardware configurations or expand ever-growing installations. Boasting PoE and Ethernet networking capabilities at the application level, any site architecture can be maintained. These network options support your temperature sensor choices, allowing you to log more data, place more sensors, or have a more flexible architecture.

On Rack – Touchscreen Display

Deliver critical information right to the field. Provide users with a system portal at the end of each rack for multi-tenanted sites, or at strategic intervals for single owner facilities. Display current temperatures and humidity readings as a heads up display. Users can also call up access data, humidity logs, and temperature trends to see how their equipment has been performing and how the environment has been maintained. Create fully customizable graphics to create a unique user experience for your occupants. The touchscreens allow personnel to make changes to the system without having to carry laptops or install separate applications.

On Rack – Access Control

Delta Controls provides a customizable access solution that allows data center facility managers to bring card access and automated security to the rack. This enables multi-tenanted facilities to allow access to individual server racks for their tenants. Setup and configuration can be done locally or offsite, giving a multitude of different options for workflow. Access logging features are built right into the system giving users the ability to see when sites were accessed. This data can be compared with work order logs, and give managers an accurate history of when their equipment was accessed. Where data security is paramount, physical security becomes a necessary precaution. For some types of data storage, such as student records or governmental data, physical security of the data is required by regulation. Delta Controls, provides facilities managers with a single platform to manage their building, lighting and their access needs. Reduce training costs, system complexity, and infrastructure cost in implementing all three systems.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.