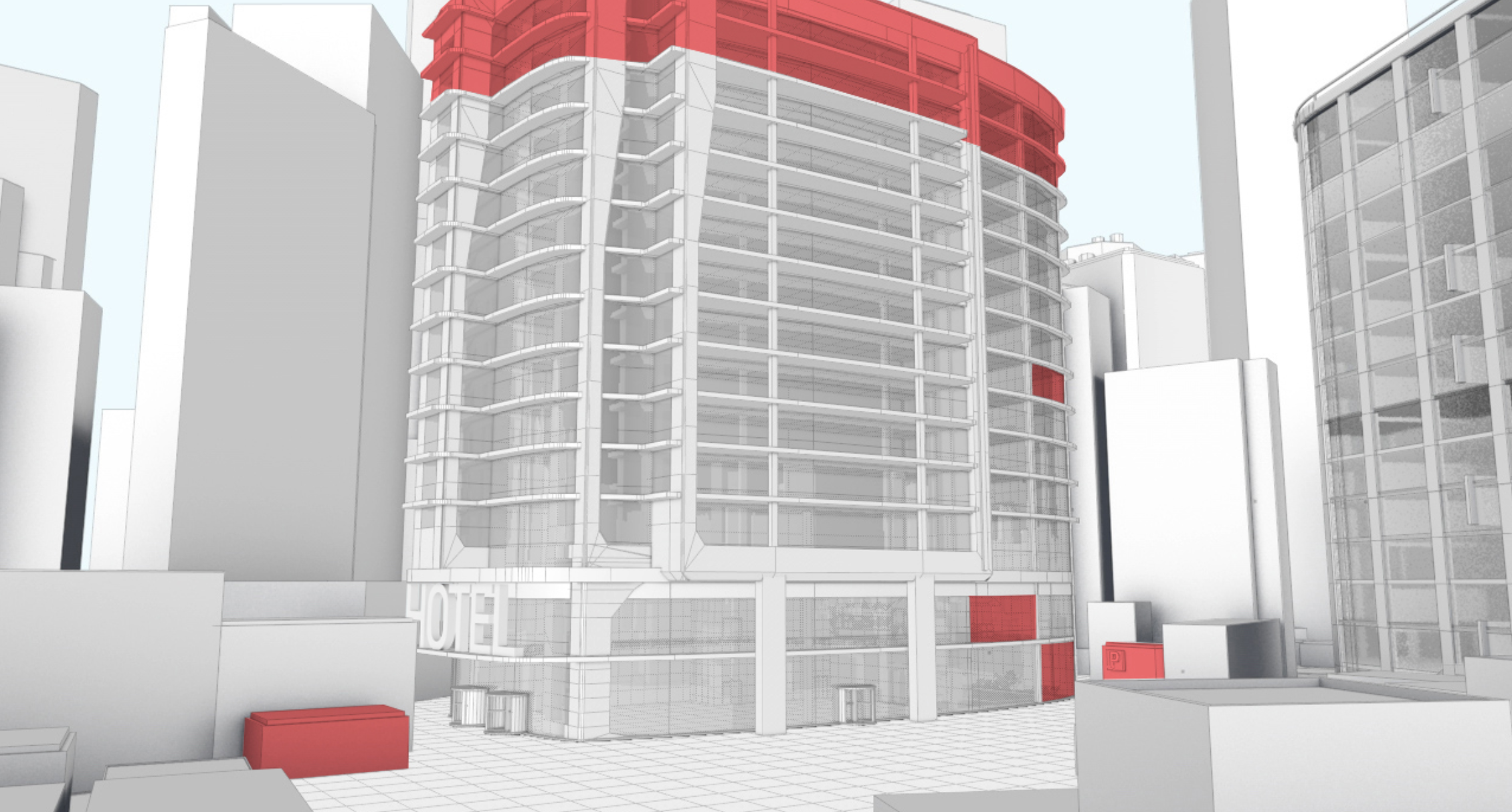

Hospitality

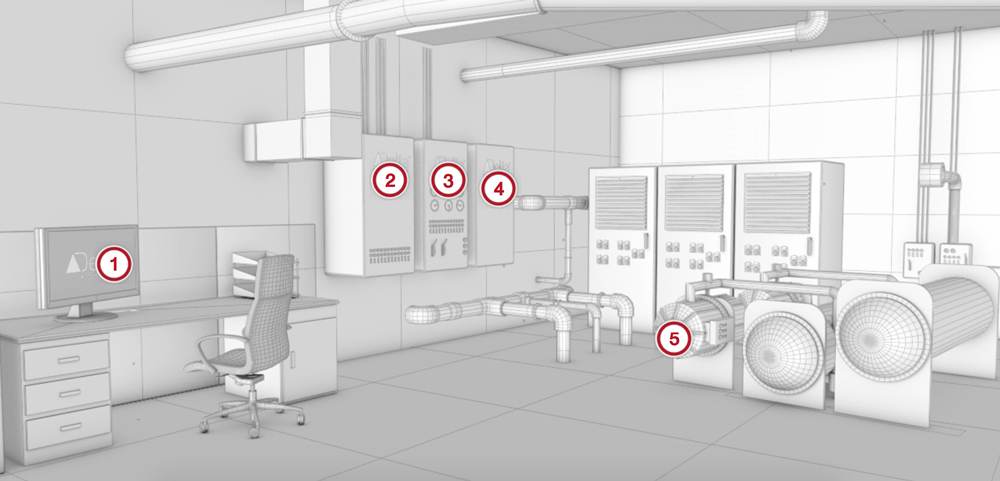

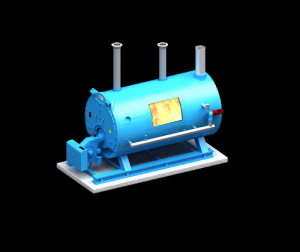

Boiler Room

Operator Workstation

Traditionally, your Building Automation System (BAS) software and interface has been tucked away in your facility manager’s office or in the corner of your building’s central plant. With all that is now being controlled in your building, bring this powerful tool out of the basement and out into the forefront where it belongs.

With this philosophy in mind, Delta Controls has developed its enteliWEB software to shine on a variety of different devices in order for you to be able to take advantage of everything it has to offer. In your lobby, create an informative and interactive energy dashboard that showcases your company’s commitment to sustainability and energy reduction. Enable your maintenance staff to troubleshoot systems in the field through tablet and smartphone interfaces optimized for these devices and increase their productivity. Open up the ability for management and other stakeholders in your company to be actively engaged with the operation and status of your building through customized dashboards, in-depth analytics and streamlined report generation.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

Meter integration

There is a saying that goes “You can’t know where you’re going until you know where you have been”. This is especially true when it comes to our buildings. In North America commercial building operation accounts for over 30% of the energy consumed, yet we don’t know where it’s going unless we are able to track it. Meters are how we solve that problem. There are meters available for gas, water, electricity, steam; if it’s used as an energy source, there is a meter for it. As a matter of fact, there is likely a multitude of different meter types available. Choosing just one of them can be a daunting task. You need a reliable and accurate meter that is suited to your usage case and meets your budget. Unfortunately, and all too often, the communication of that meter is an afterthought. This leaves you with a situation where data is being collected but you don’t have a cost effective way of pulling that data into the system where it can be interpreted.

Delta Controls has specialized in meter communications. The Delta network is capable of pulling in multiple commonly used communication protocols for meters; Modbus, M-Bus and BACnet to name a few. Meter communication is more than a technology at Delta Controls; it’s a passion. The enteliWEB software platform was built around the idea of getting more from your building. More information, more control, more energy conservation. We accomplish that by specializing in getting the information out of the system and making it easy for you to format and interpret it.

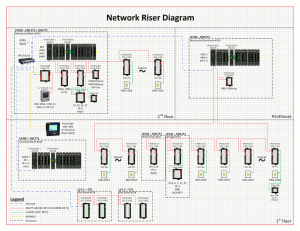

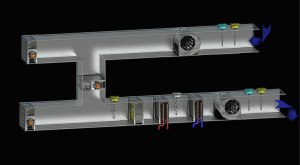

System Riser

The brains of a Building Automation System (BAS) are often located in the basement or in other out of the way locations. It used to be that a nearby computer terminal with a direct connection to a nearby panel was required in order to interact with a BAS system that communicated over a proprietary two wire network. BAS communications evolved to include an Ethernet backbone with a routing device that funnels data from a multitude of terminal devices back to the Ethernet network. The use of Ethernet allows for single or multiple terminals to plug into that network wherever an Ethernet connection is available. These Ethernet backbones are often run separately due in part to untidy communications on the IP side. It was a natural step to evolve website servers that allowed remote connections into the BAS and evolved remote alarm notification that was not reliant on a phone connection. These network architectures have remained virtually unchanged to this day.

Economic and ecological energy concerns have demanded more from our networks. More so than ever, interoperability with other devices is needed to run packaged control units like chillers, boilers and some AHU equipment. Energy conservation within a building depends on being able to pull data from multiple energy meters on site. Delta Controls has specialized in BACnet communication and has been at the forefront of BACnet compatibility since its inception. Furthermore Delta has developed integration with Modbus networks for easier integration with some packaged units and meters. Delta has also developed support for M-bus, a dedicated meter communication protocol. All these new data requirements have put further strain on conventional RS-485 networks supported by an Ethernet backbone. That is why Delta Controls has developed Ethernet controllers all the way down to the application level. This means that you can create a network architecture that is entirely comprised of Ethernet eliminating any and all possible bottlenecks in a network allowing the maximum amount of information through. Delta has invested in cutting edge technology like Power over Ethernet (PoE) and wireless communications to peripheral devices ensuring that the network you install today will be current and will be ready for the data requirements of the future.

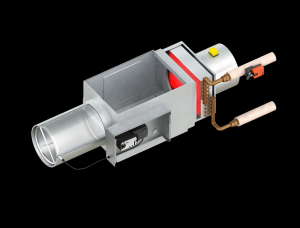

Boiler

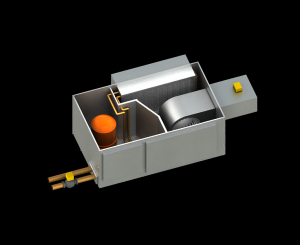

Boiler Systems

Boilers come in many types and sizes. Over the years, a relatively simple system of using natural gas flame or electric burners to rapidly heat the water in a hydronic system has grown to encompass multiple boiler systems with complicated pump systems and ecological options like heat exchangers to allow the recovery of heat from other systems or unused heat potential from equipment in the same system to be used again in the primary heating of a building. All the options for these complicated systems lead to the idea that no two systems are the same. The needs of a small or mid-sized elementary school are vastly different from a hospital or office building. A university or large medical campus may serve several buildings hot water from a singular system housed in a building called a central plant. A variety of control options are needed in order to operate all of these very different systems.

Delta offers fully programmable HVAC controllers from multiple different families to meet those needs. The power of a DSC with its large memory for complicated control schemes covers these small to mid-sized applications. But for a virtually unlimited platform, Delta Controls offers the eneliBUS system. This expandable controller houses an even larger processor and all the memory space you could need to handle the largest of central plants or hydronic systems. A hydronic system is the heart of your building or campus of buildings, providing hot water to several or hundreds of air and water systems that could be used to control comfort levels in a building. With all this responsibility, hydronic systems can represent the largest opportunity for operational energy savings, or the biggest risk of improper or sub optimal control leading to increased operating costs. Don’t trust these systems to controllers that need to be daisy chained together to attempt control or oversized controllers that are more costly than what you need. Trust in a controls offering that has the right controller to fit your need, or an expandable controller that can be sized to fit any requirement.

Kitchen

Thermostat

Thermostats: You see them everywhere and they come in a multitude of different shapes, sizes and capabilities. At their heart, regardless of their other capabilities, these devices are what provides your HVAC system with feedback data from the spaces that they are installed in as well as allowing simple user control of the basic functions in a room. Most common, are simple temperature sensors, but these devices have evolved to be able to read relative humidity, C02 concentration and even motion sensing within your space. From conventional wired sensors, to digitally communicating sensors and thermostats, to wireless sensors based on either ZigBee or enOcean protocols, the wide range of features and styles available can fit whatever requirements you have.

Delta Controls has developed their own lines of network sensors, network thermostats and room controllers built with the same reliability of all their other offerings. Since developing the world’s first BACnet listed network thermostat, Delta has created a range of different configurations and options available. From the DNS, DNT and new enteliZONE product lines, there is always a product to match every building requirement.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

Computer

Traditionally, your Building Automation System (BAS) software and interface has been tucked away in your facility manager’s office or in the corner of your building’s central plant. With all that is now being controlled in your building, bring this powerful tool out of the basement and out into the forefront where it belongs.

With this philosophy in mind, Delta Controls has developed its enteliWEB software to shine on a variety of different devices in order for you to be able to take advantage of everything it has to offer. In your lobby, create an informative and interactive energy dashboard that showcases your company’s commitment to sustainability and energy reduction. Enable your maintenance staff to troubleshoot systems in the field through tablet and smartphone interfaces optimized for these devices and increase their productivity. Open up the ability for management and other stakeholders in your company to be actively engaged with the operation and status of your building through customized dashboards, in-depth analytics and streamlined report generation.

Exhaust Fan

Exhaust Systems

Exhaust systems remove air from a space to minimize or eliminate undesirable conditions. For Indoor Air Quality (IAQ), air could be exhausted from a system to remove CO2 from a space, or to reduce the buildup of heat for building comfort. Exhaust systems are used wherever an undesirable situation is created in a space where natural ventilation will be insufficient to maintain that space. Exhaust systems can be part of a normal air conditioning strategy, or it can be a local exhaust system where a contaminant is introduced to a specific area and needs to be controlled efficiently. Exhaust systems can be simple, comprising of a fan that draws air from an indoor location to the outside of a facility, or it can be an entire system with a fan, multiple filters or an air cleaning device, and ducting leading to a stack exhaust that channels the contaminated air high above inhabited space to dissipate any contaminant.

An exhaust system may be the sole focus of your control in a system, requiring a specialized controller for its operation, or you may wish to roll an exhaust fan into a larger system’s control. Delta Controls focuses on solutions for whatever type of system you need to operate and maintain. Data centers require fast action control systems with split second alarm notification and integration to maintenance notification systems. Fume hoods for labs and educational facilities can require a host of sensory equipment to work in conjunction with manual control for reliable action in a number of scenarios. Hospitals require sensitive and fast acting systems to maintain isolation room pressure levels. Whatever your requirement is, there is a Delta controller made to fit that need.

Gas Detection System

A building gas detection system can be used to detect a range of substances. Everything from CO2 to combustible gas detection can be used to implement a controls strategy to keep building occupants safe and comfortable while maintaining economical operation of HVAC equipment. While CO2 may be detected in office spaces a wider spread of gases like CO, NOx and LPG may all need to be monitored in an area such as a car park to ensure the space is safe for both vehicles and their occupants.

The gas detection sensors may be added directly to the controls network as terminal devices communicating and coexisting with the other devices on the network. Some gas detectors act best when networked together as their own system. It is then necessary for the controls system to integrate with that network to take advantage of that sensor information. Fortunately Delta Controls provides you with a myriad of options for connecting to those third party networks.

Swimming Pool

Gas Detection System

A building gas detection system can be used to detect a range of substances. Everything from CO2 to combustible gas detection can be used to implement a controls strategy to keep building occupants safe and comfortable while maintaining economical operation of HVAC equipment. While CO2 may be detected in office spaces a wider spread of gases like CO, NOx and LPG may all need to be monitored in an area such as a car park to ensure the space is safe for both vehicles and their occupants.

The gas detection sensors may be added directly to the controls network as terminal devices communicating and coexisting with the other devices on the network. Some gas detectors act best when networked together as their own system. It is then necessary for the controls system to integrate with that network to take advantage of that sensor information. Fortunately Delta Controls provides you with a myriad of options for connecting to those third party networks.

FCU

Fan Coil Unit (FCU)

Fan Coil Unit is a term that can be used to describe a variety of air conditioning equipment depending on where you come from and what the application is but most of the time FCU is used to describe a simple system that consists of a fan with little or no ducting that is in or near the space that it supplies air to. A gas or electric heating coil is used in the FCU to provide the primary source of heat for an area or to act as a supplement to a larger system. These systems tend to be low cost alternatives to a more complicated or powerful system that would be underutilized in that area.

If you’re implementing a cost effective control strategy, the last thing you want to do is introduce expensive control but un-networked units as part of a larger system can create frustrating situations where there is little a facility manager can do about tenant complaints, or a situation where the un-networked equipment is fighting smarter equipment with access to better sensor information. There is little in the way of fault detection that can be created for this orphaned equipment. The solution is a flexible control system that can incorporate fan coil units and other simple equipment without incurring substantial cost. Delta Controls uses fully programmable controllers that can add control loops to other applications allowing for a single controller to take care of multiple pieces of equipment. For remote locations, Delta allows for a number of networking options like Ethernet to take advantage of your existing IT infrastructure to tie in controllers of all types and sizes or wireless to take control to areas you wouldn’t be able to reach otherwise.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

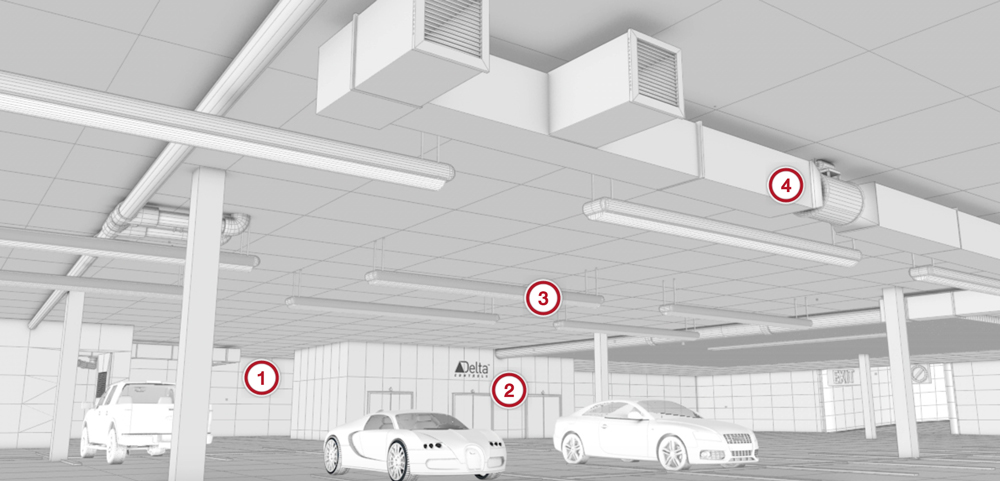

Car Park

Gas Detection System

A building gas detection system can be used to detect a range of substances. Everything from CO2 to combustible gas detection can be used to implement a controls strategy to keep building occupants safe and comfortable while maintaining economical operation of HVAC equipment. While CO2 may be detected in office spaces a wider spread of gases like CO, NOx and LPG may all need to be monitored in an area such as a car park to ensure the space is safe for both vehicles and their occupants.

The gas detection sensors may be added directly to the controls network as terminal devices communicating and coexisting with the other devices on the network. Some gas detectors act best when networked together as their own system. It is then necessary for the controls system to integrate with that network to take advantage of that sensor information. Fortunately Delta Controls provides you with a myriad of options for connecting to those third party networks.

Elevator access

Your elevator is the main access point into the rest of your building. Ensuring that people get access to the right areas of your building is of critical importance and can’t be left to chance.

Through the access control system from Delta Controls, the entire access system is integrated with the other key building systems such as lighting and HVAC control so that management is easy and simple. Built to incorporate common reader types like Wiegand and HID formats, nearly any combination of proximity readers, card swipe, passcode or even biometric peripheral devices can be used. This flexibility means that your space can be secured by whatever means needed by your

Elevator access control is radically different than simply securing a door. Multi floor button press security requires powerful hardware to run quickly and smoothly every time a card is swiped. Through Delta’s commitment to co-development throughout all product lines, you can leverage the power and I/O flexibility of the eBCON system controller to match whatever specification is needed to get the job done and done right.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

Exhaust Fan

Exhaust Systems

Exhaust systems remove air from a space to minimize or eliminate undesirable conditions. For Indoor Air Quality (IAQ), air could be exhausted from a system to remove CO2 from a space, or to reduce the buildup of heat for building comfort. Exhaust systems are used wherever an undesirable situation is created in a space where natural ventilation will be insufficient to maintain that space. Exhaust systems can be part of a normal air conditioning strategy, or it can be a local exhaust system where a contaminant is introduced to a specific area and needs to be controlled efficiently. Exhaust systems can be simple, comprising of a fan that draws air from an indoor location to the outside of a facility, or it can be an entire system with a fan, multiple filters or an air cleaning device, and ducting leading to a stack exhaust that channels the contaminated air high above inhabited space to dissipate any contaminant.

An exhaust system may be the sole focus of your control in a system, requiring a specialized controller for its operation, or you may wish to roll an exhaust fan into a larger system’s control. Delta Controls focuses on solutions for whatever type of system you need to operate and maintain. Data centers require fast action control systems with split second alarm notification and integration to maintenance notification systems. Fume hoods for labs and educational facilities can require a host of sensory equipment to work in conjunction with manual control for reliable action in a number of scenarios. Hospitals require sensitive and fast acting systems to maintain isolation room pressure levels. Whatever your requirement is, there is a Delta controller made to fit that need.

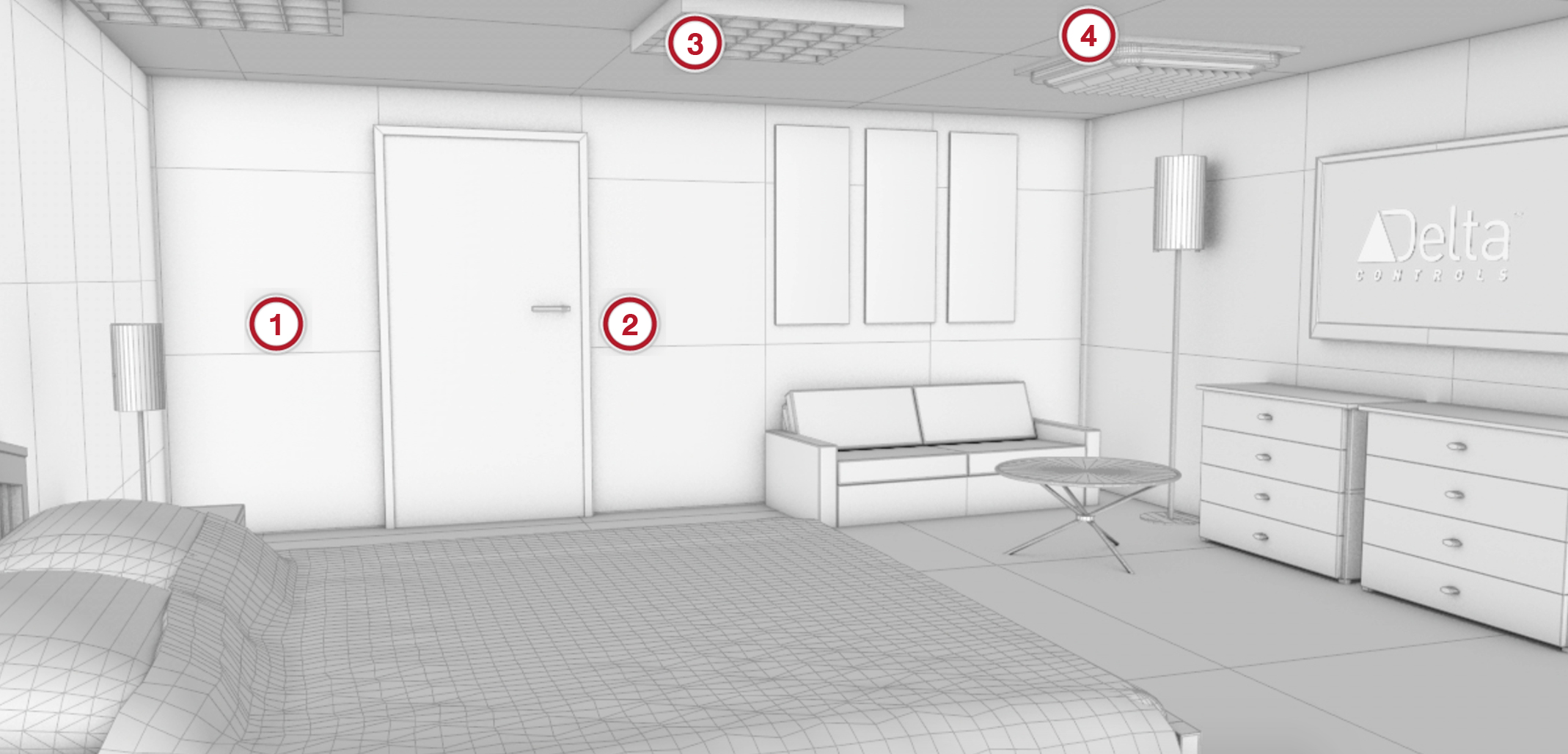

Bedroom

Thermostat

Thermostats: You see them everywhere and they come in a multitude of different shapes, sizes and capabilities. At their heart, regardless of their other capabilities, these devices are what provides your HVAC system with feedback data from the spaces that they are installed in as well as allowing simple user control of the basic functions in a room. Most common, are simple temperature sensors, but these devices have evolved to be able to read relative humidity, C02 concentration and even motion sensing within your space. From conventional wired sensors, to digitally communicating sensors and thermostats, to wireless sensors based on either ZigBee or enOcean protocols, the wide range of features and styles available can fit whatever requirements you have.

Delta Controls has developed their own lines of network sensors, network thermostats and room controllers built with the same reliability of all their other offerings. Since developing the world’s first BACnet listed network thermostat, Delta has created a range of different configurations and options available. From the DNS, DNT and new enteliZONE product lines, there is always a product to match every building requirement.

Touchscreen

Traditionally, your Building Automation System (BAS) software and interface has been tucked away in your facility manager’s office or in the corner of your building’s central plant. With all that is now being controlled in your building, bring this powerful tool out of the basement and out into the forefront where it belongs.

With this philosophy in mind, Delta Controls has developed its enteliWEB software to shine on a variety of different devices in order for you to be able to take advantage of everything it has to offer. In your lobby, create an informative and interactive energy dashboard that showcases your company’s commitment to sustainability and energy reduction. Enable your maintenance staff to troubleshoot systems in the field through tablet and smartphone interfaces optimized for these devices and increase their productivity. Open up the ability for management and other stakeholders in your company to be actively engaged with the operation and status of your building through customized dashboards, in-depth analytics and streamlined report generation.

Lighting Control

We can all forget how complicated a good lighting system can be because lighting your building should be as easy as flipping a switch. Like the endless variety of fixtures available, controlling those lights can be a complicated process involving awkward built-in logic controllers that at times results in a compromise between what you want and what the product can offer you.

Delta Controls uses the same fully programmable controller architecture in its Delta Lighting Controller (DLC) product line as in the DSC line of products. This means that the same infinitely customizable GCL+ programming language that is used to control your HVAC system can be used to create the perfect control that your building needs with no compromises.

VAV

Variable Air Volume Terminals (VAV) and Associated Equipment Types

There are a number of different terminal, airflow control equipment types. They are perhaps the most critical pieces of equipment to the perceived comfort levels of a building as they are the last stop for all the elements that go into conditioning an environment. VAV boxes are comprised of a simple round air damper operated by a dedicated controller. That controller is connected to a space temperature sensor and flow sensors for the air that enters the space. The controller’s job is to determine if the supply air is helpful to the space and determine how much of that air is allowed to flow in. There are many variations to this equipment such as additional fans to increase airflow, heating coils to allow the AHU to supply colder air that is warmed up just before entering the space, and other peripheral equipment that allows the box to further manipulate the temperature in the space.

The above is a very simplified look at what the VAV does for the inhabitants in the space. There are many mistakes and pitfalls to avoid when controlling a VAV. Have you ever felt a permanent draft in a space or area? Too much air is being supplied to the space too quickly. Have you ever had to be in a space that seems as though it’s always too hot or too cold? It may be that your air handling unit is supplying areas that are too different from each other and it won’t be able to split the difference. VAV control is critical to the comfort of a building’s occupants. Delta Controls provides all the options you need to be sure you are getting perfect control. With networking options like Ethernet and Power over Ethernet (PoE) at the zone level, there will be no corner of a building you cannot reach. Multiple controller Input and Output (I/O) configurations ensure that any configuration can be handled by the fully programmable native BACnet controllers. Multiple different VAV styles are available so you can select paired thermostats with the controllers or elect to keep those elements separate. Delta Controls knows how critical VAV control is to your comfort, and they provide all the controller types to custom fit your needs.

FCU

Fan Coil Unit (FCU)

Fan Coil Unit is a term that can be used to describe a variety of air conditioning equipment depending on where you come from and what the application is but most of the time FCU is used to describe a simple system that consists of a fan with little or no ducting that is in or near the space that it supplies air to. A gas or electric heating coil is used in the FCU to provide the primary source of heat for an area or to act as a supplement to a larger system. These systems tend to be low cost alternatives to a more complicated or powerful system that would be underutilized in that area.

If you’re implementing a cost effective control strategy, the last thing you want to do is introduce expensive control but un-networked units as part of a larger system can create frustrating situations where there is little a facility manager can do about tenant complaints, or a situation where the un-networked equipment is fighting smarter equipment with access to better sensor information. There is little in the way of fault detection that can be created for this orphaned equipment. The solution is a flexible control system that can incorporate fan coil units and other simple equipment without incurring substantial cost. Delta Controls uses fully programmable controllers that can add control loops to other applications allowing for a single controller to take care of multiple pieces of equipment. For remote locations, Delta allows for a number of networking options like Ethernet to take advantage of your existing IT infrastructure to tie in controllers of all types and sizes or wireless to take control to areas you wouldn’t be able to reach otherwise.

Heat Pump

A heat pump is a system that uses a compressor to take advantage of the evaporative cooling effect to create a desired difference of temperature in air or water. Example of these systems could be a refrigerant system or a chiller. However, the term heat pump in the HVAC and controls industry is normally applied to systems that use compressor units with an evaporator coil and a condensing coil to take advantage of a wide temperature dispersal area like outdoors or deep in the ground, to create a desired temperature change in a space. The evaporator side of the system will disperse heat and the condenser side will cool. In climates where either effect may be desired, a reversing vale is used so that wither side may heat or cool. If only heating is required, the cool temperatures deep within the earth or in a nearby body of water can be taken advantage of to create the condensing effect. Heat pumps are gaining in popularity due to their potentially low environmental impact and economical nature.

Proper control is essential to the potential savings represented by a heat pump system. Heat pumps have their limitations. In climates where the outside temp can fall too low or can raise too high for the desired condensing effect to still be able to take place on the other side of the coil, heat pumps can lose their effectiveness in conditioning a space. Supplemental systems may be required in climates that have extreme conditions. With the Delta Controls range of products, the proper control scheme will be applied to the system and any supplemental systems will be properly tied in to take maximum advantage of the economy a heat pump system represents. Preprogrammed controls may not utilize a control scheme that is optimal to your climate or will work well with the rest of your system. Delta’s range of fully programmable controllers allows a custom fit for your application. BTL listing for all of Delta’s controllers ensures smooth integration of any BACnet equipment onsite. Take advantage of the Delta line’s ability to add Modbus integration to further increase your integration options.

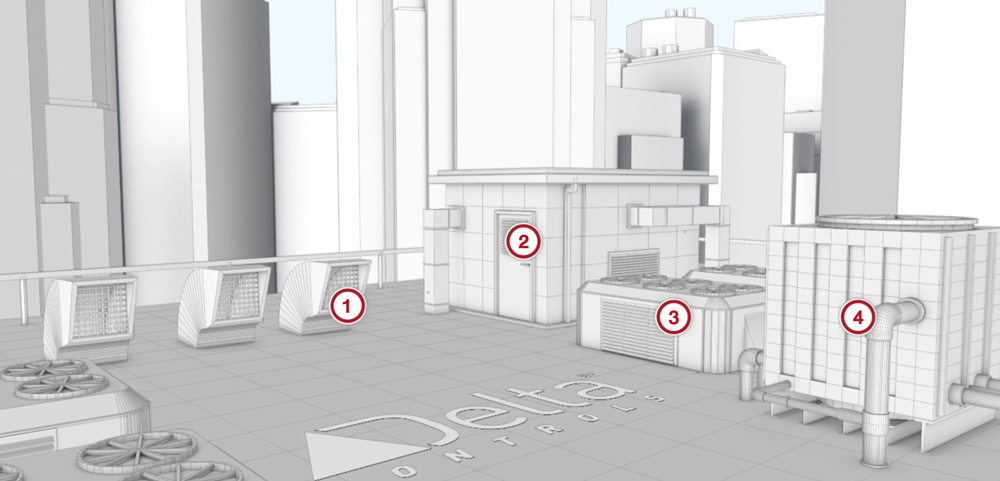

Roof

Exhaust Fan

Exhaust Systems

Exhaust systems remove air from a space to minimize or eliminate undesirable conditions. For Indoor Air Quality (IAQ), air could be exhausted from a system to remove CO2 from a space, or to reduce the buildup of heat for building comfort. Exhaust systems are used wherever an undesirable situation is created in a space where natural ventilation will be insufficient to maintain that space. Exhaust systems can be part of a normal air conditioning strategy, or it can be a local exhaust system where a contaminant is introduced to a specific area and needs to be controlled efficiently. Exhaust systems can be simple, comprising of a fan that draws air from an indoor location to the outside of a facility, or it can be an entire system with a fan, multiple filters or an air cleaning device, and ducting leading to a stack exhaust that channels the contaminated air high above inhabited space to dissipate any contaminant.

An exhaust system may be the sole focus of your control in a system, requiring a specialized controller for its operation, or you may wish to roll an exhaust fan into a larger system’s control. Delta Controls focuses on solutions for whatever type of system you need to operate and maintain. Data centers require fast action control systems with split second alarm notification and integration to maintenance notification systems. Fume hoods for labs and educational facilities can require a host of sensory equipment to work in conjunction with manual control for reliable action in a number of scenarios. Hospitals require sensitive and fast acting systems to maintain isolation room pressure levels. Whatever your requirement is, there is a Delta controller made to fit that need.

Exhaust Fan

Exhaust Systems

Exhaust systems remove air from a space to minimize or eliminate undesirable conditions. For Indoor Air Quality (IAQ), air could be exhausted from a system to remove CO2 from a space, or to reduce the buildup of heat for building comfort. Exhaust systems are used wherever an undesirable situation is created in a space where natural ventilation will be insufficient to maintain that space. Exhaust systems can be part of a normal air conditioning strategy, or it can be a local exhaust system where a contaminant is introduced to a specific area and needs to be controlled efficiently. Exhaust systems can be simple, comprising of a fan that draws air from an indoor location to the outside of a facility, or it can be an entire system with a fan, multiple filters or an air cleaning device, and ducting leading to a stack exhaust that channels the contaminated air high above inhabited space to dissipate any contaminant.

An exhaust system may be the sole focus of your control in a system, requiring a specialized controller for its operation, or you may wish to roll an exhaust fan into a larger system’s control. Delta Controls focuses on solutions for whatever type of system you need to operate and maintain. Data centers require fast action control systems with split second alarm notification and integration to maintenance notification systems. Fume hoods for labs and educational facilities can require a host of sensory equipment to work in conjunction with manual control for reliable action in a number of scenarios. Hospitals require sensitive and fast acting systems to maintain isolation room pressure levels. Whatever your requirement is, there is a Delta controller made to fit that need.

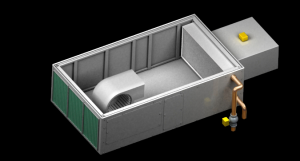

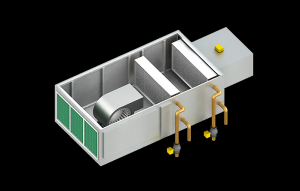

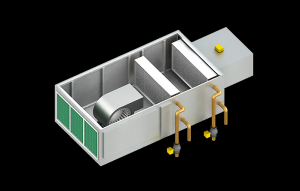

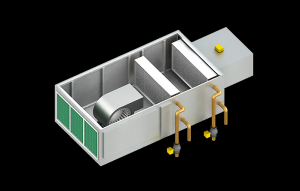

Air Handling Unit

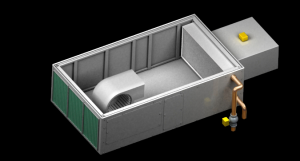

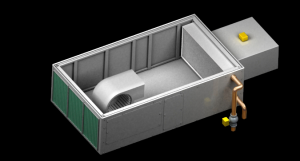

Air Handling Unit (AHU)

An AHU is a piece of mechanical equipment used to provide conditioned air to a zone or multiple areas within a building. These devices are typically installed on a building’s roof due to their relatively large size and noise, though with sufficient noise insulation and internal concrete construction an AHU may be housed internally. If the boiler and chiller equipment may be considered the heart of a building, then the air handling units may be considered the building’s lungs in terms of importance. Air handling units are critical to the comfort level of the buildings they serve because they provide conditioning to outside or “fresh” air often mixed with recycled air, which is funneled into a building’s rooms or spaces. If these units are not properly controlled and maintained, occupant comfort will be compromised, and the operation costs of a building will rise exponentially.

Delta Controls provides a variety of options to control this crucial equipment. From the economical DAC controllers to the powerful DSC family or the ever expandable enteliBUS system, you’ll find the right fit for any AHU configuration. Using any of the Delta controller families will put you at the highest compatibility with BACnet standards. When paired with enteliWEB software you’ll have one of the most advanced controls packages on the market today. With an advanced alarm management system, the ability to create custom reports in seconds, and access to a world class energy management and analytics system Delta Controls will help make your building comfortable, economical and ecologically sound.

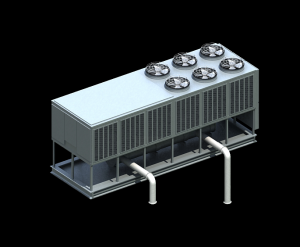

Chiller

Chiller Equipment and Cooling Systems

Chillers use an evaporation process to remove heat from water in many different ways. The type of evaporator can range from fin type evaporators like the kind you might find in a car’s system to bare tube or plate evaporators. The medium used as an evaporating agent is just as varied. Glycol, ammonia or Freon are some of the most common options. This evaporation process creates desired cooling in a water system but it also creates waste heat. A chiller can take different forms if it is air cooled, using fan exhaust systems to dissipate heat or water cooled, using water to take away the excess heat. The heat is not always wasted though, many efficient systems use a recovery system to use that heat to warm the building or supplement other heating systems. That’s not all though; a chiller system could have cooling towers that use water drop-offs and fan units to cool water in the system or heat exchangers that trade the heat in a water system to another water system or even an air system.

Delta Controls recognizes that there are many different cooling systems used in buildings today. With such a wide variety of applications like coolers for food storage and production or cooling systems for pharmaceutical processes, there are many other uses for a chiller system then just comfort control. There are Delta controller families to handle any and every application though. All Delta controllers are BTL certified ensuring easy integration of packaged solutions. Delta also offers integration to other protocols like MODbus to ensure that your equipment will be fully utilized by your system. Any cooling system will be optimally controlled because delta controllers are fully programmable using the flexible GCL+ programming language. Whether you’re using a glycol system to cool an ice rink or you’re operating a cooling tower as an ecological supplement to your building system, you’ll be able to find a Delta controller of the right size for the right price.